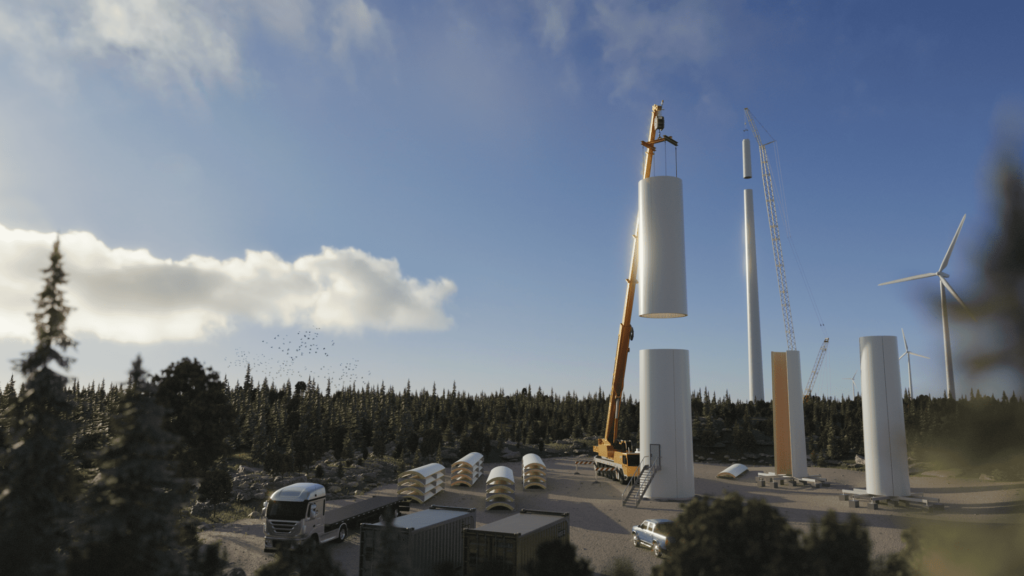

The Swedish company Modvion has developed an innovative technology that uses laminated wood instead of steel to create strong and sustainable wind turbines.

The wooden modules used by Modvion are factory-produced using laminated veneer lumber (LVL) and then stacked on regular trucks. This makes transportation more efficient and sustainable compared to steel towers that require specialized transportation. On the installation site, a small crane can assemble and stack the modules in segments, which can then be mounted by a larger crane.

According to Modvion, the potential height of a wooden wind turbine tower can reach up to 1,500 meters. But even at “just” 150 meters, wooden towers have proven to be just as robust as their steel competitors. Modvion’s wooden towers can also be used in offshore installations.

The wood currently used is Scandinavian spruce, which is abundantly available and for which reforestation exceeds harvesting. The wood used comes from sustainably managed forests certified by reforestation programs such as FSC or PEFC.

The laminated wood used by Modvion has a higher specific strength than steel, which means that lighter towers can be created without compromising their strength. Additionally, wooden towers require fewer bolts than steel towers, which means less inspection and maintenance.

But wood also has other qualities that make it a great choice for wind turbines. For example, wood has a greater capacity to capture carbon than steel. And last but not least, wood has greater fire resistance than steel and maintains its structural integrity at high temperatures.

The amount of wood used for each tower depends on the height of the tower and the load it will have to bear. For example, a 6 MW turbine places a much higher load on the structure than a 2 MW turbine. However, a typical tower ranges from 300 to 1,200 cubic meters of wood, which corresponds to the same volume of wood that grows in Swedish forests in about 5 minutes.

An eco-friendly option wind turbine tower Modvion’s wooden wind turbine towers represent an eco-friendly solution for wind energy production. Not only are they more sustainable than steel towers, but they are also highly efficient and resilient. Additionally, once the tower’s useful life is over, the wood can be reused as beams for construction, further reducing the environmental impact.

Modvion’s towers are coated with a thick layer of paint that makes them waterproof. This creates a controlled air environment inside the towers that interacts with the strength of the wood. This stable system ensures good efficiency against any moisture problems. The towers are designed according to the specifications of wind turbine manufacturers, which typically have a lifespan of 25-30 years, but the lifespan of a wooden wind turbine tower can easily exceed that of the mechanical parts of the wind turbine.

Modvion’s towers do not cost more than traditional steel towers. In fact, over time, they will be less expensive. The higher the tower, the greater the savings compared to a steel tower. The global price of steel also affects the cost, as it undergoes greater fluctuations than the price of wood.

Check out Modvion website for further information